www.beevt.com

www.beevt.com

The world’s population is expected to reach 9 billion people by the year 2050, placing extreme pressure on agriculture practices to create enough food in a sustainable manner (United Nations, 2013). BVT Inc. is taking many steps in the right direction to reduce the amount of pesticides used in oilseed and vegetable production (Bee Vectoring Technology, 2015).

What is Bee Vectoring Technology?

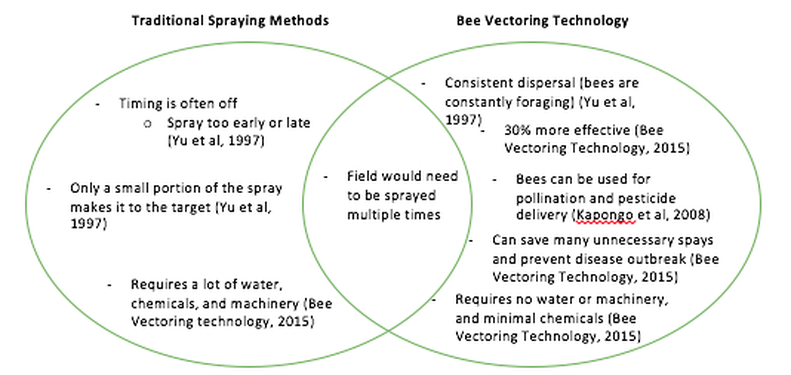

Bee Vectoring Technology uses the natural process of pollination as a delivery system of pesticides directly to the crop (Bee Vectoring Technology, 2015). The product uses Bumblebees to deliver pest controlling Vectorite as a substitute for traditional spraying methods (Bee Vectoring Technology, 2015). The bees live in a hive, as normal, but the hive has an add-on created by BVT. Their dispenser system, directs the bees to the one exit out of the hive. Bees fly through the inner tray containing the bio-pesticide powder (Vectorpak), that sticks to their legs as they exit. The process then mimics pollination, bees fly from flower to flower, leaving behind the biological agent (Bee Vectoring Technology, 2015). The whole process is organic, reducing the amount of chemicals needed for a field, requiring no machinery, and uses no water (Bee Vectoring Technology, 2015).

What is Bee Vectoring Technology?

Bee Vectoring Technology uses the natural process of pollination as a delivery system of pesticides directly to the crop (Bee Vectoring Technology, 2015). The product uses Bumblebees to deliver pest controlling Vectorite as a substitute for traditional spraying methods (Bee Vectoring Technology, 2015). The bees live in a hive, as normal, but the hive has an add-on created by BVT. Their dispenser system, directs the bees to the one exit out of the hive. Bees fly through the inner tray containing the bio-pesticide powder (Vectorpak), that sticks to their legs as they exit. The process then mimics pollination, bees fly from flower to flower, leaving behind the biological agent (Bee Vectoring Technology, 2015). The whole process is organic, reducing the amount of chemicals needed for a field, requiring no machinery, and uses no water (Bee Vectoring Technology, 2015).

Disease and Prevention Method

www.beevt.com

www.beevt.com

- Clonostachys rosea

2. Pest Prevention

Bee Vectoring Technologies is currently researching ways of integrating a pest control ingredient into the Vectorite powder (Bee Vectoring Technology, 2015). The system has been tested to incorporate more than one type of inoculant so it can be personalized to the needs of the field and crop (Bee Vectoring Technology, 2015). Some consideration has been put into the addition of Beauveria bassiana to C.rosea (Bee Vectoring Technology, 2015). There have been trials done that have shown this inoculant to be successful in the control of pests (Kapongo et al, 2008).

http://modernfarmer.com/2014/07/putting-bees-back-work/

http://modernfarmer.com/2014/07/putting-bees-back-work/

Effects on Bumble Bees

Bees are a necessity to the success of many crops across the globe, but they are beginning to decrease in population (Bee Vectoring Technology, 2015). This can be because of habitat loss, pathogens, climate change, etc, but a major player is agrochemicals (Potts et al, 2010). Pesticide use is resulting in the loss of a large percentage of bee populations (Potts et al, 2010). When sprays are used on a field the bees go to pollinate and get the chemicals on them, bringing them into the hive (Bee Vectoring Technology, 2015).

BVT uses bees that are commercially reared and bred specifically for the job of pollination and dispersal of the product (Bee Vectoring Technology, 2015). The bees do not consume the product, only carry it around to the flowers (Bee Vectoring Technology, 2015). Bumble bees forage regularly regardless of delivering the inoculant, therefore the delivery system follows the natural process of pollination (Yu et al, 1997). The set-up of the Vectorpak protects the rest of the hive from contamination (Yu et al, 1997). The inoculant is only in the Vectorpak, which they only pass through as they leave the hive, so bees aren’t exposed to the inoculant for long periods of time (Yu et al, 1997). If a spray needs to be applied to the field, a cover can be put in place to only allow the bees to enter the hive, not exit (Bee Vectoring Technology, 2015). Thus protecting the bees from the chemicals (Bee Vectoring Technology, 2015).

Bees are a necessity to the success of many crops across the globe, but they are beginning to decrease in population (Bee Vectoring Technology, 2015). This can be because of habitat loss, pathogens, climate change, etc, but a major player is agrochemicals (Potts et al, 2010). Pesticide use is resulting in the loss of a large percentage of bee populations (Potts et al, 2010). When sprays are used on a field the bees go to pollinate and get the chemicals on them, bringing them into the hive (Bee Vectoring Technology, 2015).

BVT uses bees that are commercially reared and bred specifically for the job of pollination and dispersal of the product (Bee Vectoring Technology, 2015). The bees do not consume the product, only carry it around to the flowers (Bee Vectoring Technology, 2015). Bumble bees forage regularly regardless of delivering the inoculant, therefore the delivery system follows the natural process of pollination (Yu et al, 1997). The set-up of the Vectorpak protects the rest of the hive from contamination (Yu et al, 1997). The inoculant is only in the Vectorpak, which they only pass through as they leave the hive, so bees aren’t exposed to the inoculant for long periods of time (Yu et al, 1997). If a spray needs to be applied to the field, a cover can be put in place to only allow the bees to enter the hive, not exit (Bee Vectoring Technology, 2015). Thus protecting the bees from the chemicals (Bee Vectoring Technology, 2015).

www.beevt.com

www.beevt.com

Benefits

Bee vectoring follows a natural process which results in a low impact on the environment (Bee Vectoring technology, 2015). There is no machinery or water required for the process, and very little chemicals used (Bee Vectoring Technology, 2015). The use of pollinators to deliver the inoculant not only reduces the pressures of pests and pesticides on plants but also improves pollination (James et al, 2008). It has also been seen to result in higher yields because of the improved seed quality and germination (James et al, 2008). The better quality of the fruit results in a longer shelf life which decreases the amount of food waste (Bee Vectoring Technology, 2015). Farmers to be able to minimize their use of sprays with the product, resulting in less water usage, and decreased amounts of chemicals that make it into the waterways (Bee Vectoring Technology, 2015).

Manufacturer

Bee Vectoring Technology is only made by Bee Vectoring Technologies Inc. which is a Canadian company based in Mississauga, Ontario (Bee Vectoring Technology, 2015). The company recently opened a state of the art facility in Mississauga where their research and production occurs (Bee Vectoring Technology, 2015). This facility will allow the production of $100 million dollars worth of product in a year (Bee Vectoring Technology, 2015).

Production

In creating the Vectorpak, large quantities of the Clonostachys rosea are produced in the BVT lab and put into the plastic Vectorpak container and sealed (Bee Vectoring Technology, 2015). To make the dispenser systems, it costs about $2 CAN to produce (personal communication, November 28, 2016). Since Bee Vectoring Technologies Inc. is still an up and coming company, there is no set cost for the product if bought by a farmer (personal communication, November 28, 2016). Usually, farmers that are interested in the product, have bees of their own already, but some bees come from other bee suppliers in that area (personal communication, November 28, 2016).

Bee vectoring follows a natural process which results in a low impact on the environment (Bee Vectoring technology, 2015). There is no machinery or water required for the process, and very little chemicals used (Bee Vectoring Technology, 2015). The use of pollinators to deliver the inoculant not only reduces the pressures of pests and pesticides on plants but also improves pollination (James et al, 2008). It has also been seen to result in higher yields because of the improved seed quality and germination (James et al, 2008). The better quality of the fruit results in a longer shelf life which decreases the amount of food waste (Bee Vectoring Technology, 2015). Farmers to be able to minimize their use of sprays with the product, resulting in less water usage, and decreased amounts of chemicals that make it into the waterways (Bee Vectoring Technology, 2015).

Manufacturer

Bee Vectoring Technology is only made by Bee Vectoring Technologies Inc. which is a Canadian company based in Mississauga, Ontario (Bee Vectoring Technology, 2015). The company recently opened a state of the art facility in Mississauga where their research and production occurs (Bee Vectoring Technology, 2015). This facility will allow the production of $100 million dollars worth of product in a year (Bee Vectoring Technology, 2015).

Production

In creating the Vectorpak, large quantities of the Clonostachys rosea are produced in the BVT lab and put into the plastic Vectorpak container and sealed (Bee Vectoring Technology, 2015). To make the dispenser systems, it costs about $2 CAN to produce (personal communication, November 28, 2016). Since Bee Vectoring Technologies Inc. is still an up and coming company, there is no set cost for the product if bought by a farmer (personal communication, November 28, 2016). Usually, farmers that are interested in the product, have bees of their own already, but some bees come from other bee suppliers in that area (personal communication, November 28, 2016).

Patent restraints

Bee Vectoring Technology has applied for patents in about 40 countries around the world (Bee Vectoring Technologies Inc., 2016). This includes three patents; the dispenser system, the Vectorite™ brand, and the active ingredient required for the product (BVT-CR7) (Bee Vectoring Technology, 2015). The company has recently gained 2 of 3 patents in the U.S, and is awaiting the result of the third patent for the active ingredient in the system (Bee Vectoring Technologies Inc., 2016). The company has gained approval for the patents in Canada, China, Russia, and Australia, and is awaiting the results from the other countries (Personal communication, November 28, 2016).

Benefits to Canada

2. Strengthen Trade Relationship Between Canada and Nepal

Canada and Nepal, for a long time, have had an established relationship (Government of Canada, 2013). Trade and investment between the countries are modest (Government of Canada, 2013). Exports from Canada to Nepal was $7.1 million, and imports from Nepal accounted $11.7 million (Government of Canada, 2013). Canada mainly exports machinery, paper, vegetables, etc to Nepal with a particular interest in energy equipment, irrigation and engineering, transportation, etc (Government of Canada, 2013).Though Bee Vectoring Technology does not fall under any of these main categories, adding this technology to the list of Canadian exports would help continue to build strong trading ties with Nepal (Government of Canada, 2013).

Bee Vectoring Technology has applied for patents in about 40 countries around the world (Bee Vectoring Technologies Inc., 2016). This includes three patents; the dispenser system, the Vectorite™ brand, and the active ingredient required for the product (BVT-CR7) (Bee Vectoring Technology, 2015). The company has recently gained 2 of 3 patents in the U.S, and is awaiting the result of the third patent for the active ingredient in the system (Bee Vectoring Technologies Inc., 2016). The company has gained approval for the patents in Canada, China, Russia, and Australia, and is awaiting the results from the other countries (Personal communication, November 28, 2016).

Benefits to Canada

- Creation of Jobs

2. Strengthen Trade Relationship Between Canada and Nepal

Canada and Nepal, for a long time, have had an established relationship (Government of Canada, 2013). Trade and investment between the countries are modest (Government of Canada, 2013). Exports from Canada to Nepal was $7.1 million, and imports from Nepal accounted $11.7 million (Government of Canada, 2013). Canada mainly exports machinery, paper, vegetables, etc to Nepal with a particular interest in energy equipment, irrigation and engineering, transportation, etc (Government of Canada, 2013).Though Bee Vectoring Technology does not fall under any of these main categories, adding this technology to the list of Canadian exports would help continue to build strong trading ties with Nepal (Government of Canada, 2013).